Embark on a journey through the realm of MRP software, a revolutionary tool transforming the manufacturing landscape. Discover the ins and outs of this powerful technology that is reshaping production processes worldwide.

Delve deeper into the realm of MRP software and uncover its impact on optimizing manufacturing operations for businesses of all sizes.

Overview of MRP Software

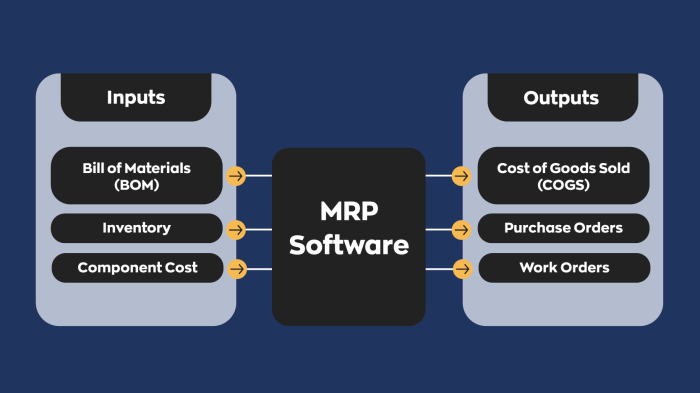

MRP (Material Requirements Planning) software is a crucial tool used in manufacturing industries to effectively plan, schedule, and manage the materials needed for production. It helps streamline the production process by ensuring that the right materials are available at the right time, in the right quantities.

Key Features of MRP Software

- Bill of Materials (BOM) Management: MRP software allows users to create and maintain detailed lists of materials required for production.

- Inventory Control: It helps in tracking inventory levels, reorder points, and lead times to prevent stockouts or overstock situations.

- Scheduling and Planning: MRP software assists in generating production schedules, determining manufacturing lead times, and optimizing production processes.

- Forecasting: By analyzing historical data and market trends, MRP software can predict future material requirements and production needs.

- Reporting and Analysis: It provides comprehensive reports on material usage, order status, and production performance for informed decision-making.

Benefits of Implementing MRP Software

- Improved Efficiency: By automating manual processes and optimizing material flow, MRP software helps reduce lead times and increase overall productivity.

- Cost Savings: Proper inventory management and production planning lead to reduced inventory carrying costs and minimize waste from overproduction.

- Enhanced Accuracy: MRP software ensures accurate demand forecasting, inventory tracking, and order processing, reducing errors and improving customer satisfaction.

- Better Decision-Making: With real-time insights into material availability and production status, manufacturers can make informed decisions to meet customer demands effectively.

- Competitive Advantage: Implementing MRP software enables companies to respond quickly to market changes, adapt production processes, and stay ahead of competitors.

Types of MRP Software

When it comes to MRP software, there are primarily two types available in the market: cloud-based solutions and on-premise systems. Each type has its own set of advantages and considerations for different manufacturing businesses.

Cloud-based MRP Software vs. On-premise Solutions

Cloud-based MRP software is hosted on remote servers and accessed through the internet, offering flexibility, scalability, and accessibility from anywhere with an internet connection. On the other hand, on-premise solutions are installed locally on the company's servers and require maintenance and updates from the IT team.

- Cloud-based MRP software:

- Examples: NetSuite, Plex Systems, Odoo

- Advantages: Lower upfront costs, automatic updates, scalability, remote access

- Considerations: Data security, internet dependency, subscription-based pricing

- On-premise MRP software:

- Examples: SAP, Microsoft Dynamics 365, Epicor

- Advantages: Control over data, customization options, no internet dependency

- Considerations: Higher upfront costs, IT maintenance, limited accessibility

Scalability of MRP Software for Different Business Sizes

MRP software comes in different versions and configurations to cater to the needs of small, medium, and large manufacturing businesses.

- Small Businesses:

- Features: Basic inventory management, production planning, and scheduling

- Examples: Fishbowl, E2 Shop System, JobBOSS

- Medium Businesses:

- Features: Advanced inventory control, demand forecasting, supplier management

- Examples: IQMS, Global Shop Solutions, Infor CloudSuite Industrial

- Large Businesses:

- Features: Enterprise resource planning (ERP) integration, multi-site management, compliance tracking

- Examples: Oracle NetSuite, SAP S/4HANA, Microsoft Dynamics 365 for Finance and Operations

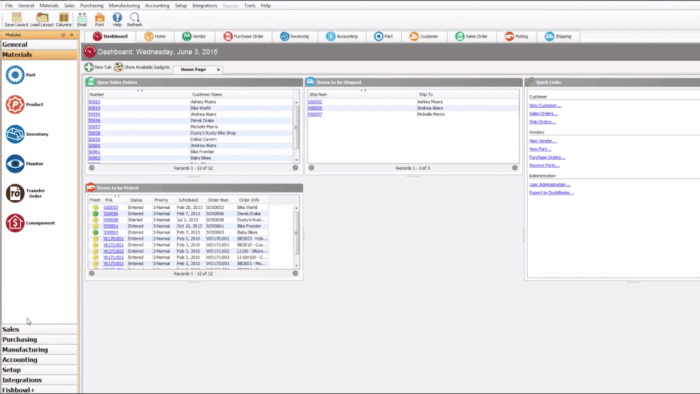

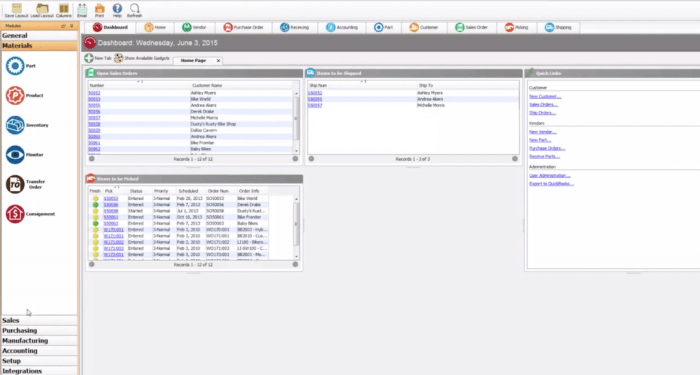

Implementation of MRP Software

Implementing MRP software in a manufacturing setting involves several key steps to ensure a successful integration and utilization of the system. It is essential to carefully plan and execute the implementation process to maximize the benefits of MRP software.

Steps involved in implementing MRP software:

- Assess current processes and needs: Conduct a thorough analysis of existing processes, inventory management, and production requirements to identify areas where MRP software can improve efficiency.

- Select the right MRP software: Choose a software solution that aligns with the specific needs and goals of your manufacturing operations.

- Data migration and system setup: Transfer relevant data to the new system and configure the software to meet the unique requirements of your business.

- Training and education: Provide comprehensive training to employees on how to use the MRP software effectively to optimize production planning and inventory management.

- Testing and validation: Conduct thorough testing of the system to ensure accuracy and reliability before fully implementing the MRP software across the organization.

- Continuous monitoring and improvement: Regularly monitor the performance of the MRP software and make necessary adjustments to enhance efficiency and productivity.

Common challenges faced during the implementation process and how to overcome them:

- Resistance to change: Employees may be hesitant to adopt new technology. To overcome this challenge, provide clear communication about the benefits of the MRP software and offer adequate training and support.

- Data accuracy and integrity: Ensuring data accuracy during the migration process is crucial. Implement data validation procedures and regular audits to maintain data integrity.

- Integration with existing systems: Compatibility issues with existing software systems can arise. Work closely with IT experts to address integration challenges and ensure seamless operation.

Training requirements for employees when adopting MRP software:

- Basic understanding of manufacturing processes: Employees should have a foundational knowledge of manufacturing operations to effectively utilize the MRP software for production planning and inventory management.

- Software training: Provide comprehensive training sessions on how to navigate the MRP software, input data, generate reports, and interpret system outputs.

- Ongoing support and education: Offer continuous support and resources to help employees adapt to the new system and maximize the benefits of MRP software in day-to-day operations.

Integration with Other Systems

When it comes to maximizing the efficiency and effectiveness of manufacturing processes, integrating MRP software with other systems is crucial. This integration allows for seamless communication and data sharing between different departments within an organization, leading to improved decision-making and streamlined operations.

Integration with ERP Systems

Integrating MRP software with ERP systems is essential for ensuring a holistic view of the entire manufacturing process. By connecting MRP data with other business functions such as finance, human resources, and supply chain management, organizations can make more informed decisions and optimize resource allocation.

Integration with Inventory Management Systems

MRP software can be integrated with inventory management systems to ensure accurate tracking of raw materials, work-in-progress, and finished goods. This integration enables real-time monitoring of inventory levels, reducing the risk of stockouts and overstocking, ultimately leading to cost savings and improved customer satisfaction.

Role in Streamlining Production through CRM Systems

By integrating MRP software with CRM systems, organizations can enhance customer relationship management and streamline production processes. This integration allows for better forecasting of customer demand, personalized product offerings, and improved order fulfillment, resulting in increased customer loyalty and overall operational efficiency.

Customization and Configuration

Customization and configuration are essential aspects of MRP software that allow businesses to tailor the system to meet their specific manufacturing needs. By customizing the software, companies can optimize production scheduling, streamline processes, and improve overall efficiency. Let's dive into the details:

Customization Options

- Custom Fields: MRP software often allows users to create custom fields to capture unique data points relevant to their operations. This can include specific product attributes, manufacturing processes, or quality control metrics.

- Workflow Configuration: Businesses can customize workflows within the MRP software to match their production processes. This includes defining approval hierarchies, routing steps, and task assignments.

- Reporting Templates: MRP software offers the flexibility to create custom reports and dashboards to track key performance indicators (KPIs) and monitor production metrics in real-time.

Production Scheduling Optimization

- Capacity Planning: MRP software can be configured to consider machine capacities, labor availability, and material lead times to optimize production schedules and avoid bottlenecks.

- Priority Rules: Users can set up priority rules within the software to automatically assign urgency levels to orders based on factors like due dates, customer preferences, or production constraints.

- Simulation Tools: Some MRP systems offer simulation capabilities that allow users to model different production scenarios and evaluate the impact on scheduling before implementation.

User Permissions and Access Control

- Role-Based Access: MRP software enables administrators to define user roles and permissions, restricting access to sensitive data and functionalities based on job responsibilities.

- Audit Trails: The system can track user activity and changes made within the software, providing transparency and accountability while ensuring data integrity.

- Data Security: Configurable security settings allow businesses to implement data encryption, authentication protocols, and other measures to safeguard sensitive information stored in the MRP system.

Reporting and Analytics

When it comes to MRP software, reporting and analytics play a crucial role in tracking production performance and improving efficiency. Let's dive into how these features can benefit your manufacturing processes.

Reporting Capabilities

MRP software provides in-depth reporting capabilities that allow you to track various aspects of production performance. These reports can include details on inventory levels, order statuses, lead times, and more. By analyzing these reports, you can identify trends, spot inefficiencies, and make data-driven decisions to optimize your operations.

Role of Analytics

Analytics in MRP software are essential for identifying bottlenecks in production processes. By analyzing data such as production cycle times, resource utilization, and order fulfillment rates, you can pinpoint areas that are causing delays or inefficiencies. This insight enables you to take corrective actions to streamline operations and improve overall production efficiency.

Key Performance Indicators (KPIs)

- Inventory Turnover Rate: Measures how quickly inventory is being used and replenished.

- On-Time Delivery: Tracks the percentage of orders delivered on time to customers.

- Capacity Utilization: Evaluates how effectively manufacturing resources are being utilized.

- Order Cycle Time: Calculates the time it takes to process an order from start to finish.

Conclusion

In conclusion, MRP software stands as a beacon of efficiency and productivity in the manufacturing sector. With its ability to streamline processes and enhance performance, it is undoubtedly a game-changer for businesses looking to stay ahead in a competitive market.

Dive into the world of MRP software and unlock the potential for unprecedented growth and success.

Detailed FAQs

What are the key features of MRP software?

Key features include materials planning, production scheduling, inventory management, and demand forecasting.

How can MRP software benefit small businesses?

MRP software helps small businesses optimize their production processes, reduce waste, and improve overall efficiency.

Is training required for employees to use MRP software?

Yes, training is essential to ensure employees understand how to effectively use MRP software for maximum benefit.

Can MRP software be integrated with existing inventory management systems?

Yes, MRP software can be seamlessly integrated with existing inventory management systems to enhance efficiency and accuracy.

What are some common challenges faced during MRP software implementation?

Common challenges include data migration issues, resistance to change, and ensuring proper system configuration.

![Best Construction ERP Software [2024 Edition]](https://health.bandungnews.id/wp-content/uploads/2025/10/Top-10-Best-Construction-ERP-Software-to-Use-in-2024-1-120x86.jpg)